Coffee harvesting is a meticulous and time-sensitive process that determines the quality and flavor of that morning cup of joe you enjoy every day. From the lush coffee plantations to the skilled hands of farmers, the journey of coffee begins with the harvest. Delicate coffee cherries, filled with the potential for rich flavors, are carefully selected and harvested by skilled workers. Understanding how coffee is harvested unveils the fascinating journey from seed to cup, showcasing the dedication and expertise required to bring us the perfect brew.

The Coffee Plant

The coffee plant, scientifically known as Coffea, is a tropical evergreen shrub that belongs to the Rubiaceae family. It is the source of the coffee beans that eventually make their way into our cups. The growth cycle of a coffee plant starts with the germination of its seeds, which are commonly referred to as coffee beans.

There are two main species of coffee plants that dominate the global coffee industry: Coffea arabica and Coffea robusta. Coffea arabica, often referred to as “Arabica,” is considered the superior species, known for its high-quality beans and complex flavors. On the other hand, Coffea robusta, also known as “Robusta,” is hardier and more resistant to diseases, making it a popular choice for blending and instant coffee production.

Coffee plants thrive in specific environmental conditions. They prefer tropical climates with temperatures ranging between 60°F and 70°F (15°C and 24°C). The ideal altitude for coffee cultivation varies depending on the species. Arabica coffee plants thrive at higher altitudes, typically between 2,000 and 6,000 feet (600 to 1,800 meters), while Robusta coffee plants can tolerate lower altitudes, ranging from sea level to 2,000 feet (600 meters).

In addition to climate and altitude, the soil type also plays a crucial role in coffee cultivation. Coffee plants prefer well-draining soils with good fertility and a slightly acidic to neutral pH level. Volcanic soils are highly prized for their rich mineral content and excellent drainage properties, providing an ideal environment for coffee plants to grow and develop their distinct flavors.

Understanding the coffee plant and its preferred growing conditions helps us appreciate the intricate relationship between nature and the coffee we savor.

Understanding Coffee Cherries

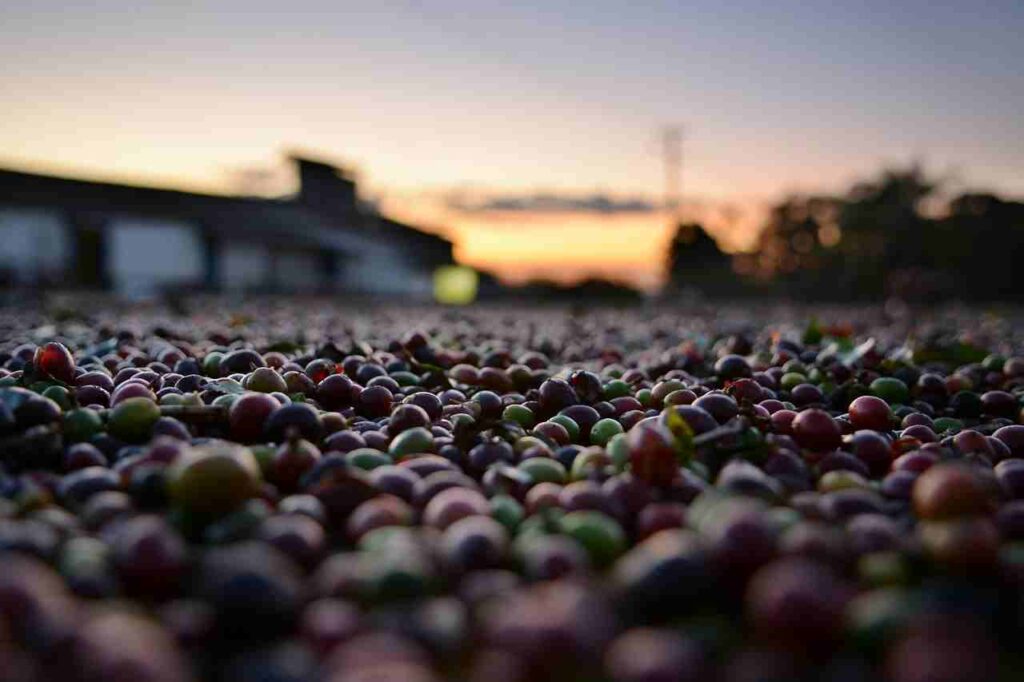

At the heart of every cup of coffee are the coffee cherries, the fruit that holds the precious coffee beans. Understanding the different stages of coffee cherry ripeness is crucial in determining the flavor and quality of the resulting coffee.

Coffee cherries undergo a process of maturation as they grow on the coffee plant. They start as green cherries, gradually transforming in color and flavor as they ripen. The stages of ripeness typically include green, yellow, orange, and finally, red cherries. Each stage imparts distinct characteristics to the coffee beans they encase.

Green cherries are underripe and lack the sweetness and complex flavors associated with fully matured coffee. As the cherries progress in ripeness, they develop higher sugar content and undergo chemical changes that contribute to the desired flavors. Yellow and orange cherries indicate a stage of partial ripeness, while red cherries are considered fully ripe and offer the optimal balance of sugars, acidity, and other flavor compounds.

Selective harvesting plays a crucial role in ensuring the best quality beans. Skilled coffee harvesters are trained to selectively pick only the ripe cherries, leaving behind the underripe and overripe ones. This careful selection is vital as unripe cherries lack the desired sweetness and can contribute undesirable flavors to the coffee. Overripe cherries, on the other hand, may exhibit fermented or overly fruity flavors that can affect the overall taste profile.

By practicing selective harvesting, coffee farmers can guarantee that only the highest quality beans are harvested, resulting in a superior cup of coffee. This attention to detail and commitment to quality control during the harvesting process is what sets apart specialty coffee from mass-produced alternatives.

How is Coffee Harvested – Harvesting Methods

Coffee harvesting involves the careful and precise removal of ripe coffee cherries from the coffee plant. There are two primary methods of coffee harvesting: hand-picking and strip-picking, each with its own advantages and applications.

Hand-picking is considered the traditional and most labor-intensive method of coffee harvesting. Skilled workers carefully inspect the coffee trees, selecting only the ripe cherries for harvest. This selective harvesting ensures that only the highest quality beans are picked, as unripe or overripe cherries are left on the tree to fully mature. Hand-picking requires experienced harvesters who can quickly distinguish between ripe and unripe cherries, ensuring optimal flavor and quality. This method is commonly practiced for high-quality Arabica coffee, where the emphasis is on preserving the unique characteristics of the beans.

In contrast, strip-picking is a mechanized method typically used in larger coffee plantations. With this method, mechanical harvesters or specialized equipment strip off all the cherries from the coffee trees at once, regardless of their ripeness. While strip-picking offers increased efficiency and speed, it may result in a mix of ripe, underripe, and overripe cherries being harvested together. This method is often employed for Robusta coffee or in regions where large-scale production is the priority.

Both harvesting methods play an important role in the coffee industry, catering to different needs and market demands. Hand-picking allows for meticulous selection of ripe cherries, preserving the unique flavor profiles of specialty coffees. Strip-picking, on the other hand, enables the efficient harvest of large quantities of coffee, making it suitable for commercial coffee production on a larger scale.

The choice of harvesting method depends on various factors, including the type of coffee being cultivated, the size of the plantation, and the desired flavor and quality standards. Let’s have a look in a bit more detail:

Hand-Picking Harvesting Process

Hand-picking is a meticulous and labor-intensive harvesting method that involves selecting and extracting coffee cherries by hand. This process requires skilled workers who possess a deep understanding of coffee cherries and the ability to carefully choose only the ripest ones for extraction.

The hand-picking process begins with trained harvesters meticulously inspecting the coffee plants. They carefully examine each branch, selectively choosing only the cherries that have reached their optimal ripeness. This selective approach ensures that only the highest quality cherries are picked, contributing to the overall excellence of the final coffee product.

Once the ripe cherries have been identified, the harvesters delicately pluck them from the branches. This task demands precision and finesse, as the cherries need to be carefully detached without damaging the surrounding foliage or unripe cherries that will continue to mature.

There are many advantages of hand-picking. Firstly, it allows for unparalleled quality control. Skilled harvesters have the ability to discern the ideal ripeness of each coffee cherry, ensuring that only the finest ones are selected. This level of attention to detail leads to a superior coffee with well-developed flavors, nuanced aromas, and a balanced acidity.

Hand-picking also contributes to environmental sustainability. Unlike mechanical harvesting methods that strip all cherries from the branches, hand-picking allows for a selective approach. This means that unripe cherries can remain on the plant to continue maturing, leading to a more sustainable and efficient use of resources.

Also, hand-picking supports local communities by providing employment opportunities. Coffee harvesters play a crucial role in the coffee production chain and are often valued members of their communities. Their expertise and dedication ensure the production of high-quality coffee while contributing to the economic well-being of the regions where coffee is grown.

Strip-Picking Harvesting Process

In contrast to the meticulous hand-picking method, strip-picking is a harvesting process that involves removing all the coffee cherries from a branch at once. This method is often employed in large-scale coffee plantations, where efficiency and productivity are key considerations.

During strip-picking, a harvester runs their hand along a coffee branch, swiftly sweeping away all the cherries in one motion. This rapid and sweeping motion allows for a faster harvesting process compared to hand-picking. By removing all the cherries at once, strip-picking maximizes efficiency and enables greater productivity, making it well-suited for large-scale coffee production.

One of the primary advantages of strip-picking is its efficiency. With the ability to harvest multiple cherries simultaneously, strip-picking significantly reduces the time and labor required compared to hand-picking. This efficiency is particularly beneficial for coffee plantations with vast areas of cultivation and a high volume of cherries to be harvested.

Strip-picking also offers increased productivity. The swift removal of cherries from the branches allows for a faster turnover, enabling harvesters to cover more ground within a shorter period. This expedited process contributes to timely harvesting and a more streamlined production workflow.

However, there are potential drawbacks associated with strip-picking. One concern is the potential damage to unripe cherries. Since all the cherries on a branch are harvested together, it is possible that some of them may not have reached their optimal ripeness. This can result in a lower-quality coffee with less developed flavors and aromas. It requires careful monitoring and adherence to proper ripeness standards to mitigate this risk.

Another consideration is the potential impact on selective harvesting. With strip-picking, the opportunity for selectively harvesting only the ripest cherries is diminished. This may result in a wider range of ripeness levels among the harvested cherries, which can impact the overall flavor profile and consistency of the coffee.

It’s important to note that while strip-picking is associated with large-scale coffee production, some coffee producers employ a hybrid approach, combining strip-picking with selective hand-picking. This hybrid method allows for increased efficiency while still maintaining some level of cherry selection.

Post-Harvest Processing

After coffee cherries have been harvested, a series of post-harvest processing steps are undertaken to transform the cherries into green coffee beans. These processes, including pulping, fermentation, washing, and drying, play a crucial role in shaping the flavor and quality of the final coffee beans.

Each post-harvest processing step has a significant impact on the flavor and quality of the coffee beans. Fermentation, in particular, can impart unique characteristics to the beans, enhancing their flavors and aromas. The duration and conditions of fermentation can vary, leading to a wide range of flavor profiles in the final coffee.

Post-harvest processing methods can vary depending on geographical regions and coffee varieties. Different regions have developed their own traditional processing techniques, passed down through generations.

Here are the key processing methods:

Wet Processing Method

The wet processing method, also known as washed processing or wet-hulling (also Giling Basah), is one of the primary techniques used in coffee post-harvest processing. This method involves several steps to remove the outer layers of the coffee cherry and reveal the coffee beans.

- Sorting and Processing: Wet processing begins with the cherries being sorted and inspected for quality. They are then passed through a pulping machine that removes the outer skin, or exocarp, and the pulp, leaving the coffee beans covered in a sticky layer called mucilage. The beans, still covered in mucilage, are then transferred to fermentation tanks.

- Fermentation Process: During fermentation, naturally occurring enzymes break down the mucilage, helping to remove it from the beans. The length of fermentation can vary depending on factors such as climate and desired flavor profiles. After fermentation, the beans are thoroughly washed to remove any remaining mucilage.

- Drying the Beans: Once the washing process is complete, the coffee beans are typically spread out on raised drying beds or patios to dry under the sun. The beans are regularly turned and monitored to ensure even drying and prevent mold or rotting. The drying process can take several days to a few weeks, depending on weather conditions.

- Milling and Hulling: After the beans have dried to the desired moisture content, they undergo milling and hulling to remove the outer parchment layer that encases the beans. This reveals the green coffee beans, which are then ready for roasting.

Wet processing is known for producing coffee with bright acidity, clarity of flavor, and a clean taste. The method helps remove impurities and substances that can contribute to off-flavors. Proper fermentation, washing, and drying techniques are crucial in ensuring the desired flavor characteristics.

This method requires a significant amount of water, both for pulping the cherries and for washing the beans. While water is essential in this process, it can pose environmental challenges, especially in regions where water resources are limited. Implementing water-saving technologies and responsible water management practices can help mitigate these challenges.

Wet processing is favored for producing specialty coffees that showcase the unique flavor profiles of different coffee varieties. It requires careful attention to detail, skilled labor, and appropriate infrastructure for handling large volumes of cherries.

While the wet processing method presents challenges such as water usage and potential fermentation issues, when executed properly, it can result in exceptional cups of coffee that highlight the nuances and complexities of the beans’ flavors.

Dry Processing Method

The dry processing method, also known as natural processing, is an alternative approach to post-harvest processing in coffee production. This method involves drying the coffee cherries intact, allowing them to naturally remove the outer layers and dry while still encasing the coffee beans.

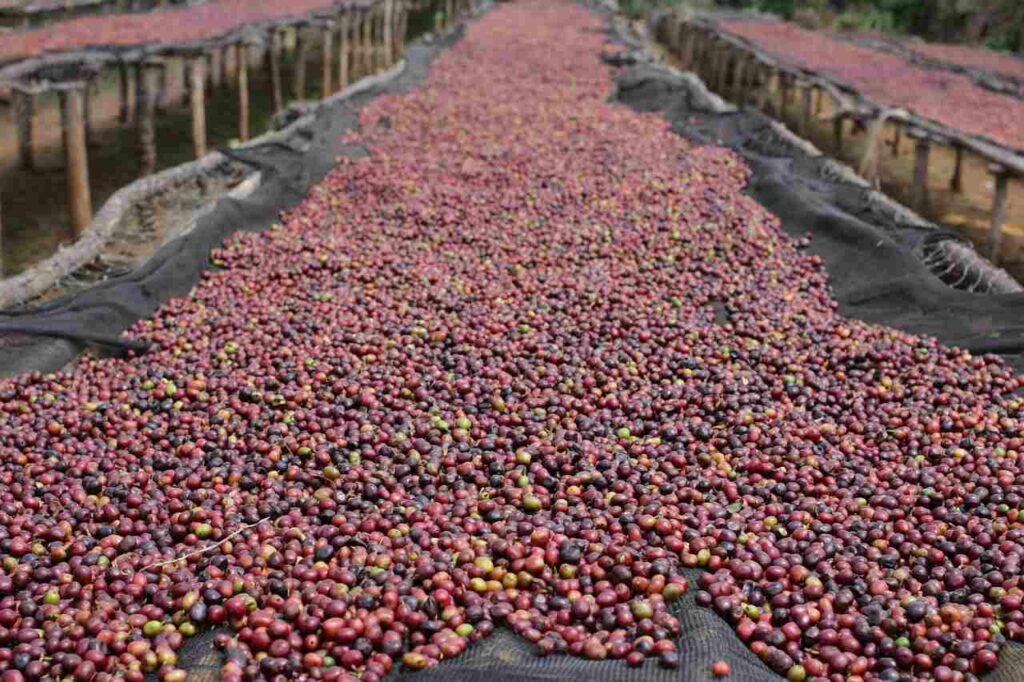

- Sorting and Processing: In the dry processing method, freshly harvested cherries are carefully sorted to remove any damaged or unripe fruits. The cherries are then spread out in a single layer on drying beds or patios, where they are exposed to the sun and air.

- Drying the Cherries: As the cherries dry, the outer skin, pulp, and mucilage naturally dry out and become brittle. The cherries are periodically turned and raked to ensure even drying and prevent mold or fermentation. This process can take several weeks, depending on weather conditions, humidity, and desired moisture content.

- Hulling and Polishing: Once the cherries have dried to the optimal moisture level, they are ready for hulling. Hulling involves removing the dried outer skin, pulp, and parchment layer from the coffee beans, revealing the green coffee beans inside. The beans are then polished to remove any remaining particles.

- Sorting and Grading: After hulling and polishing, the coffee beans go through a sorting process to remove any defective or discolored beans. They are graded based on size, shape, and density to ensure uniformity in the final product.

- Flavor Profile: The dry processing method is known to impart unique flavor characteristics to the coffee beans. It often results in coffee with full body, pronounced sweetness, and intense fruitiness. The extended contact between the beans and the fruit during drying can contribute to complex flavor profiles.

Dry processing requires favorable weather conditions with ample sunlight and low humidity to ensure proper drying. It is more suitable for regions with dry climates. However, this method is susceptible to risks such as uneven drying, fermentation, and mold development if not carefully monitored. Proper attention to detail and quality control measures are essential to produce high-quality coffee.

Dry processing has been practiced for centuries and is deeply rooted in coffee-producing regions with limited access to water resources. It offers sustainability advantages by reducing water usage and the need for complex machinery, making it more accessible for small-scale farmers.

The dry processing method provides a distinct flavor profile appreciated by coffee enthusiasts seeking fruit-forward and naturally sweet coffees. Its unique characteristics and connection to traditional coffee-growing regions make it a preferred method for specific coffee varieties and regions.

However, the method requires careful management, expertise, and favorable environmental conditions to achieve consistent quality and prevent undesirable flavor defects.

Hybrid and Specialty Processing Methods

In addition to the wet and dry processing methods, there are hybrid and specialty processing methods that offer unique approaches to post-harvest coffee processing. These methods aim to push the boundaries of flavor and experiment with different techniques to create distinctive and exceptional coffees.

- Hybrid Processing: Hybrid processing methods combine elements of both wet and dry processing. They often involve selectively fermenting or drying specific coffee lots to enhance certain flavor profiles or create unique cup characteristics. Hybrid processing methods can vary widely, and coffee producers may experiment with different variations to achieve desired results.

- Carbonic Maceration: Carbonic maceration is a specialty processing method inspired by winemaking techniques. In this method, coffee cherries are placed in a controlled fermentation environment with limited oxygen. The cherries undergo anaerobic fermentation, resulting in unique flavors and aromatic compounds. Carbonic maceration often produces coffees with distinct fruity and wine-like characteristics.

- Honey Processing: Honey processing, also known as pulped natural processing, involves partially removing the cherry’s outer skin and pulp while allowing the mucilage to remain on the coffee beans during drying. The beans are then dried with the sticky, honey-like mucilage intact. This process can result in coffees with a balanced flavor profile, showcasing sweetness and acidity with varying degrees of fermentation complexity.

- Natural Processing Variations: Natural processing variations involve modifying the traditional dry processing method to experiment with different drying techniques, times, or environmental conditions. These variations aim to influence the flavor profile and create unique cup profiles. Examples include extended fermentation periods, raised bed drying, or controlled shading during the drying process.

- Experimental Processing Methods: Specialty coffee producers and roasters continually explore and innovate with experimental processing methods. These methods may involve unconventional techniques such as anaerobic fermentation, barrel aging, freeze-drying, or other creative approaches. The goal is to push the boundaries of flavor and create extraordinary coffee experiences.

Hybrid and specialty processing methods can result in coffees with exceptional and nuanced flavor profiles. The careful manipulation of fermentation, drying, and other factors can enhance sweetness, acidity, body, and complexity in the cup. Specialty coffees processed using these methods often command higher prices due to their uniqueness and quality.

These methods require meticulous attention to detail and close collaboration between coffee producers, processors, and roasters. These methods often embody the artisanal craft of coffee production and reflect the passion for innovation within the specialty coffee community.

Hybrid and specialty processing methods provide avenues for creativity and exploration within the coffee industry. They allow coffee producers to experiment with different techniques and variables to uncover new flavor profiles and elevate the coffee experience.

These methods contribute to the diversity and excitement of the specialty coffee market while showcasing the skill and dedication of coffee professionals.

Coffee Harvesting Challenges

Coffee harvesting presents numerous challenges for farmers, ranging from labor shortages to unpredictable weather conditions. These challenges can significantly impact the livelihoods of coffee farmers and the overall coffee production process.

One of the primary challenges faced by coffee farmers during the harvesting season is the availability of skilled labor. Harvesting coffee cherries is a labor-intensive task that requires precision and expertise to ensure the selection of ripe cherries. However, in many regions, there is a shortage of experienced workers, leading to increased costs and potential delays in harvesting.

Another significant challenge is the unpredictable weather patterns that can affect coffee crops. Excessive rainfall or drought can disrupt the flowering and fruiting cycles of coffee plants, leading to lower yields and compromised bean quality. Additionally, extreme weather events such as storms or frost can cause significant damage to coffee trees and result in the loss of entire harvests.

The impact of climate change further exacerbates the challenges faced by coffee farmers. Rising temperatures, changing rainfall patterns, and the spread of pests and diseases pose a threat to coffee cultivation. To mitigate these risks, sustainable practices are increasingly adopted, including shade-grown cultivation, agroforestry, and the use of organic farming methods. These practices not only promote environmental conservation but also contribute to the long-term viability of coffee farming.

Economic factors also play a crucial role in coffee harvesting. Market prices can fluctuate, affecting the profitability of coffee farmers. Volatile prices can make it difficult for farmers to plan and invest in their crops. Initiatives such as fair trade certification aim to address this issue by providing better prices and fair working conditions for farmers. By supporting fair trade, consumers can contribute to the sustainability of the coffee industry and the well-being of coffee farming communities.